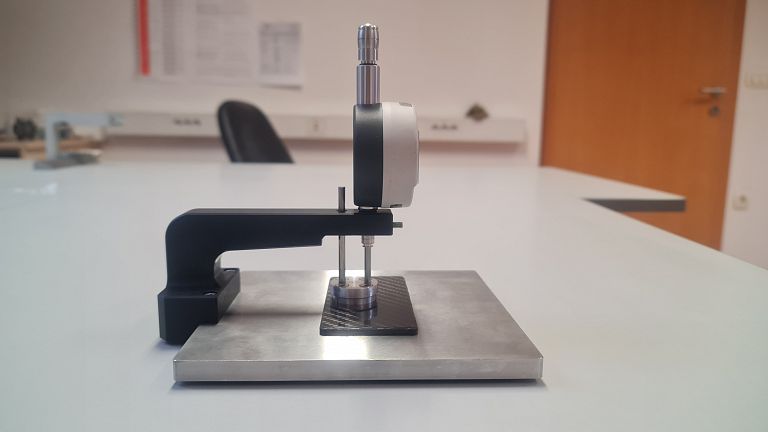

Our company has developed a custom measuring device for blister cavity depth, designed for a specific customer and intended for use on packaging lines as a support tool during the adjustment of forming tools for foil shaping. The device enables fast and reliable measurement of forming depth or blister thickness, which is essential for the proper setup of tablet packaging processes in the pharmaceutical industry.

To achieve top-level measurement precision and stability, we used a combination of carefully selected materials: stainless steel, aluminum alloy, and carbon fiber. This selection provides an optimal balance between strength, wear resistance, and low weight, ensuring ease of use and long-term reliability. The construction, combined with a high-quality dial gauge, delivers excellent repeatability and measurement accuracy. In addition, the large measuring plate helps prevent any unwanted blister deformation during measurement.

Our measuring device is an indispensable tool for precise and efficient adjustment of forming tools on pharmaceutical packaging lines.